Ciblage précis des dégâts causés par les insectes ! L'usine de haricots de Dalian adopte le trieur à rayons X SDV, éliminant plus de 99 % des défauts des pois.

Ciblage précis des dégâts causés par les insectes ! L'usine de haricots de Dalian adopte le trieur à rayons X SDV, éliminant plus de 99 % des défauts des pois.

June 19, 2025SDV, leader des technologies de tri avancées, a installé avec succès son détecteur à rayons X intelligent de pointe dans une importante usine de transformation de haricots à Dalian, en Chine. Le système a démontré des performances exceptionnelles, offrant une solution révolutionnaire au défi persistant de l'usine : les dégâts causés par les insectes sur les pois verts. Depuis sa mise en service, le système a atteint un niveau record. taux d'élimination des défauts impressionnant dépassant 99 %, éliminant ainsi efficacement un problème de qualité de longue date et gagnant les éloges du client.

La détection précise résout les problèmes de l'industrie

Les pois verts sont sensibles aux infestations d'insectes pendant leur croissance et leur stockage, ce qui entraîne des cavités internes (dégâts d'insectes) difficiles à détecter. Ces défauts altèrent non seulement l'apparence et le goût du produit, mais présentent également des risques pour la sécurité alimentaire, ce qui représente un défi majeur pour l'industrie de la transformation des haricots. Les méthodes traditionnelles de tri manuel ou optique souffrent souvent d'une faible efficacité et d'un taux d'échec élevé, et peinent à répondre aux exigences des marchés nationaux et internationaux de haute qualité. L'usine de Dalian, fortement impactée par ce problème, avait besoin d'une solution plus efficace et plus précise de toute urgence.

La puissance des rayons X offre des résultats « exceptionnels »

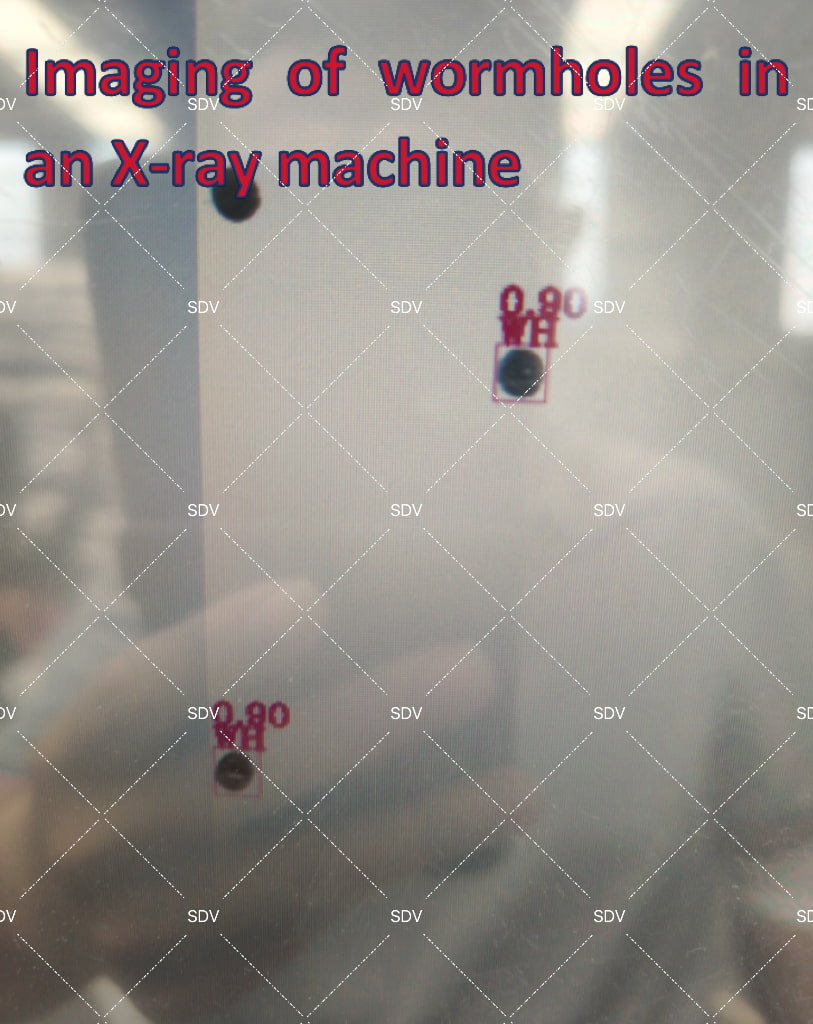

Le détecteur à rayons X intelligent fourni par SDV utilise une technologie à rayons X performante pour détecter clairement les cavités internes causées par les insectes et les corps étrangers (comme les restes d'insectes) dans les pois, dissimulant ainsi les défauts les plus dissimulés. Équipé de détecteurs haute sensibilité et d'algorithmes de traitement d'image avancés, le système effectue une identification et un rejet rapides et précis en quelques millisecondes.

Les performances du système de l’usine de Dalian ont dépassé les attentes. Les données opérationnelles démontrent systématiquement un taux de détection et d’élimination des dommages causés par les insectes dépassant 99 %. Ce chiffre remarquable signifie que presque tous les pois défectueux sont identifiés avec précision et automatiquement rejetés, améliorant considérablement la pureté et la qualité du produit final.

Les éloges des clients établissent une référence dans le secteur

« Cet équipement est une véritable révolution ! » s'est exclamé le responsable du contrôle qualité de l'usine de transformation des haricots de Dalian. « Les dégâts causés par les insectes ont été notre plus grand casse-tête en matière de contrôle qualité pendant des années. Cela exigeait une main-d'œuvre considérable et des pois défectueux passaient encore entre les mailles du filet, suscitant des plaintes de la part des clients. Depuis l'installation du détecteur à rayons X de SDV, la qualité de nos pois triés s'est considérablement améliorée : les pois endommagés par les insectes sont quasiment éliminés. Ce taux d'élimination de plus de 99 % est tout simplement exceptionnel ! Cela a considérablement réduit nos risques qualité, amélioré la satisfaction client et renforcé notre compétitivité sur le marché. Nous adressons nos plus sincères félicitations et nos plus sincères remerciements à SDV pour les performances de son équipement et son service exceptionnel ! »

SDV : Engagé pour la sécurité alimentaire et l'amélioration de la qualité

Cette mise en œuvre réussie à l'usine de transformation de haricots de Dalian réaffirme le leadership technologique de SDV dans le secteur du tri et de l'inspection des aliments. L'entreprise s'engage à appliquer des technologies de pointe à la transformation des aliments, fournissant à ses clients internationaux des solutions efficaces et fiables pour la détection de corps étrangers et le classement de la qualité, garantissant ainsi la sécurité alimentaire à la source et valorisant les produits.

« Nous sommes ravis de constater que notre technologie à rayons X résout efficacement un défi majeur pour notre client de Dalian et offre des avantages économiques et de marque significatifs », a déclaré le directeur commercial de SDV. « Atteindre un taux d'élimination des dégâts causés par les insectes supérieur à 99 % démontre notre capacité technique et, surtout, notre engagement à tenir nos promesses envers nos clients. Nous continuerons d'innover pour permettre à davantage de transformateurs alimentaires d'évoluer vers des opérations plus sûres, plus efficaces et plus intelligentes. »

droits d'auteur

© 2026 Suzhou Dream Vision Co., Ltd. Tous les droits sont réservés

.Plan du site

| Blog

| Xml | politique de confidentialité  RÉSEAU PRIS EN CHARGE

RÉSEAU PRIS EN CHARGE